RISERS/FILTERS, FEEDING AIDS,

& GATING

Together, Risering, Filtering, and Gating all play a key role in the process of casting metals, guarenteeing quality and integrity of the final product.

Joy-Mark and ASK Chemicals full line of fiber ceramic risers, sprues, gating tile, pouring basins, formed shapes, and hot topping has been a great product line for all of our customers!

Joy-Mark

Feeding Aids & Filters

Insulating and Exothermic Riser Sleeves

Reliable, cost effective approach for optimizing feeding efficiency, improving quality, and lowering cost.

The Joy-Mark CF series of insulating riser sleeves and CFX series of exothermic riser sleeves provide the foundry with a reliable cost effective approach for optimizing feeding efficiency, improving quality, and lowering cost. Stringent manufacturing procedures and quality control standards ensure that your risering needs will be met on a continual basis.

Joy-Mark riser sleeves are available in a variety of compositions to meet your casting needs. They feature a wide variety of standard riser sleeve shapes and sizes.

Advantages:

- Reduction of heat loss allowing smaller risers to be used

- Improved casting yield

- Reduction of melting and cleaning room costs

- Reduction of piping and shrinkage

- Maintain integrity - will not contaminate sand system

- Improved soundness of castings

- Light weight, yet strong compositions to withstand molding forces

- Low smoke and fumes

- Reduction of remelt volumes

- Easily modified to create special feeding effects while maintaining thermal performance

CF100, CF200, CF300 insulating, and CFX 700 and CFX 760 exothermic resin-bonded and starch-bonded (W) straight sleeves are available in the following standard sizes:

- 1" to 9" diameter in 1/2" increments up to 18" tall, 1/2" wall standard

- 9" to 16" diameter in 1" increments up to 12" tall, 1/2" to 1" wall available

- 16" to 30" diameter in 2" increments up to 12" tall, 1" to 2" wall available

CFX800 exothermic resin-bonded sleeves are available in the following sizes:

- 3" to 6" diameter in 1/2" increments to 12" high, 1/2" to 1" wall available

- 6" to 14" diameter in 1" increments to 12" high, 1/2" to 1-1/2" wall available

- 16" to 28" diameter in 2" increments to 12" high, 1-1/2" to 2" wall available

Dip Ladles and Skimmers

Ensuring safety, quality, and efficiency in the handling of molten metal.

Joy-Mark produces a variety of ceramic fiber dip ladles and slag skimmers for use in all metal types. Their insulating CF300W rigidized composition is used for maximum service temperature and strength. These thermally efficient ladles and skimmers offer an economical and effective alternative to metal ladles and skimmers. Their durability enables the foundry to use them over and over again with little or no maintenance.

- *During their first use, Joy-Mark dip ladles and skimmers should be immersed in the metal bath and held there until off-gassing ceases. After this initial burn-out, it is not necessary to preheat these tools for subsequent use!

- Light-weight for maneuverability and ease of handling

- Low thermal mass to reduce heat loss from metal to ladle or skimmer

- Highly insulating to reduce heat loss to atmosphere

- Strong and durable to allow multiple reuses

- Non-wetting to molten metal

- No preheating necessary after first use

- No coating necessary

- Economical compared to metal and full ceramic ladle and skimmer alternatives

DIP LADLES

Available in a wide range of sizes and capacities, they are convenient for the routine pouring of test bars, metallurgical samples, and even small size production castings. All of our dip ladles feature a double pouring lip design with a nominal 1" wall thickness.

- DL-2, 2.5, and 3 - feature a 1/2" wide metal reinforcement ring embedded inside. The attachment handle is 1/4" by 1/2" and protrudes 5" from the ladle.

- DL-5 and DL-6 - use a 1" wide perforated reinforcement ring. The attachment handle is 1" perforated metal with 3/*" holes, 1/4" thick, and extends 5-1/2" from the dip ladle. The DL-5 may also be used to remove slag from ductile iron holding furnaces where there is limited space to remove slag. One or several 3/4" holes are drilled into the bottom. In this mode, the DL-5 has higher capacity to hold slag and a smaller footprint than a normal skimmer.

- DL-6.5 and DL-7 - have a large capacity and has a heavy-duty "L-bracket" for secure attachment. The bracket is 2-1/4" wide, with two 7/16" mounting holes, and protrudes 4" from the ladle.

SKIMMERS

Our skimmers have nine 1/2" drain holes and are supplied in either a 6-1/2" or 8" diameter. Each is 1" thick with a 1/2" wide metal reinforcement ring embedded inside. The attachment handle is 1/4" by 1/2" and protrudes 5-1/2" from the skimmer.

Shank Ladles and Ladle Liners

Ensuring safety, efficiency, and the quality of castings.

Joy-Mark produces a wide range of ceramic fiber ladle liners for use in all metal types. Their insulating CF300WR rigidized composition is used for all aluminum applications as well as smaller sizes in copper base and ferrous applications. Their insulating CF300WLR rigidized composition is used for larger sizes in copper base and ferrous applications. These thermally efficient ladles offer an economical method of transferring molten metal to production molds. Their durability enables the foundry to use them over and over again with little or no maintenance.

- Light-weight for maneuverability and ease of handling

- Low thermal mass to reduce heat loss from metal to ladle

- Highly insulating to reduce heat loss to atmosphere

- Strong and durable to allow multiple reuses

- Non-wetting to molten metal

- No preheating necessary after first preparation

- No coating necessary

- Economical compared to metal and full ceramic ladle alternatives

LADLES and LADLE LINERS

Joy-Mark manufactures ladles with both ID and OD forming process.

- 409 Ladle - is an ID formed part, which maximizes density inside the ladle to resist metal penetration and ladle erosion. It also features a double pouring lip configuration. Single lip configurations are also available.

The ID formed style is an excellent choice as a ladle liner. They are available in a wide range of capacities. OD formed ladles may also be used as ladle liners. - 308 Ladle - OD formed ladle featuring excellent control of OD dimensions guaranteeing a good fit in a pouring shank. The higher outside density also improves the resistance to physical damage from a pouring shank. The 308 features a double lip configuration, but single lip styles are also available. It comes in a wide variety of sizes.

*Joy-Mark LADLE LINERS are available in various sizes and capacities (at 80% full).

Higher capacity ladles for shank pouring utilize an imbedded support frame to ensure ladle integrity through repeated uses.

- 407 Ladle - An ID formed part with an imbedded support frame in a single pour lip configuration.

- 458 Ladle - An ID formed part with an imbedded support frame in a single lip configuration. Double lip configurations are also available.

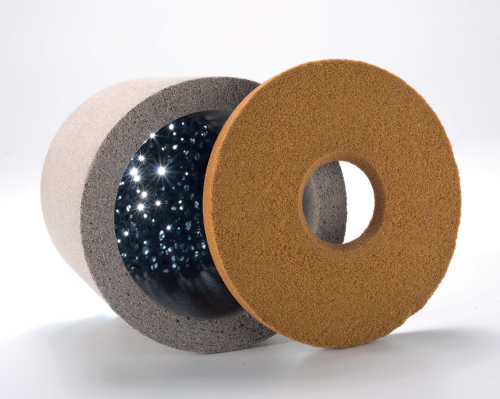

Direct Pour Filters and Filter Sleeves

Increasing metal yields and establishing greater production efficiencies.

Joy-Mark, Inc. offers ceramic foam filters for use in direct pour, in-line filtration, investment casting and casthouse operations. Higher temperature and specialty formulations with standard and custom shapes and PPI are available.

Features

- Eliminates traditional runners

- Reduces in-gates

- Removes impurities from metal

- Promotes directional solidification

- Uses less metal

- Simple design & application

- Improve casting quality

- Many sizes and styles

Benefits

- Increases metal yield and reduces costs

- Lowers cleaning room options

- Virtually eliminates inclusion defects

- Feeds the casting & reduces shrinkage

- Pour more castings per heat

- Lowers planning & design costs

- Less machining & improved cosmetics

- Maximizes filtering capacity & flow rates

CFF Z

Partially Stabilized Zirconia for Steel Filtration

Foundry Applications: Stainless and High Alloy Steels, Carbon and Low Alloy Steels, Other

CFF C

CeraCat+ high temperature ceramic with carbon addition for Steel Filtration without preheat

Foundry Applications: Stainless and High Alloy Steels, Carbon and Low Alloy Steels, Other

CFF SiC

Silcon Carbide for economocial iron and non-ferrous filtering applications

Foundry Applications: Aluminum, Gray/Ductile Iron, Other

CFF LD

Low Density filter for Aluminum direct pour applications

Foundry Applications: Aluminum

Reduce casting production costs by increasing yields with Filter Sleeves for direct pouring.

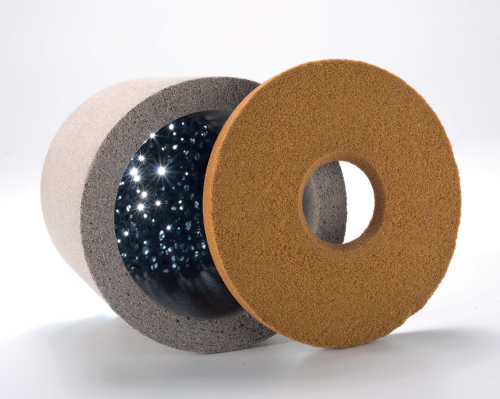

Filter Risers

During the casting process, filter risers can be used to cover the essential tasks of filtering and feeding the casting.

Due to the flexibility of the system, filter risers can be used in steel, iron, and non-ferrous castings as well as in all common molding processes (vertical/horizontal/machine and hand molding). The filter used must be adjusted to suit the casting metal and the desired flow rate.

Advantages:

- Increased yield

- Reduced space requirement for the casting system leads to more efficient usage of the pattern, or reducing the molding box size

- Reliable feeding

- Reduction in cleaning costs

- Improved cast surface

To get more product information:

POINT RISERS

POINT-RISER

PXT - Series

Applications: grey cast iron and ductile iron

POINT-Riser

PKXT - Series

Applications: grey cast iron and ductile iron

POINT-Riser

ME-N on sleeve basis

Application: grey cast and ductile iron

Hot Topping

Powdered compound that is added to the sprue and riser to hold heat in the riser and continue to feed the casting.

It's primary purpose is to reduce heat loss from the molten metal in the riser, thereby maintaining it in a liquid state for a longer time. This helps ensure that the molten metal in the riser feeds into the casting as it solidifies, reducing shrinkage defects and improving the integrity of the final product.

Joy-Mark Hot Toppings feature a unique combination of insulating and exothermic characteristics for improved feeding of castings. They are available for both ferrous and non-ferrous applications. Foundries are able to reduce production costs due to the topping compounds abilities.

- Reduce riser heat loss to atmosphere

- Maintain open riser to assure continued feeding

- Reduce piping in risers

- Assure integrity of the casting

- Reduce piping in risers

- Assure integrity of the casting

- Increase metal yield

- Easy to apply

* Joy-Mark Hot Topping Compounds may be selected based on specific properties.

- Metal application

- Expandable

- Sensitivity to reaction

- Type of ash

- Heat output

- Insulation

- Fume

- Bulk density

NF-31

Non-Ferrous Metal Application

- Expandable: No

- Sensitivity of Reaction: Rapid

- Type of Ash: Firm Crust

- Heat Output: Moderate

- Insulation: Moderate

- Fume: Moderate

- Bulk Density: High

NF-31EH

Non-Ferrous Metal Application

- Expandable: No

- Sensitivity of Reaction: Rapid

- Type of Ash: Firm Crust

- Heat Output: High

- Insulation: Moderate

- Fume: Moderate

- Bulk Density: High

IX-20

Iron and Steel Metal Application

- Expandable: Yes

- Sensitivity of Reaction: Slow

- Type of Ash: Soft Crust

- Heat Output: Moderate

- Insulation: High

- Fume: Low

- Bulk Density: Moderate

IX-24

Iron and Steel Metal Application

- Expandable: Yes

- Sensitivity of Reaction: Slow

- Type of Ash: Soft Crust

- Heat Output: Moderate

- Insulation: High

- Fume: Low

- Bulk Density: Moderate

IX-44

Iron and Steel Metal Application

- Expandable: Yes

- Sensitivity of Reaction: Rapid

- Type of Ash: Soft Crust

- Heat Output: Very High

- Insulation: High

- Fume: Low

- Bulk Density: Low

IX-46

Iron and Steel Metal Application

- Expandable: Yes

- Sensitivity of Reaction: Moderate

- Type of Ash: Soft Crust

- Heat Output: Moderate

- Insulation: Very High

- Fume: Low

- Bulk Density: High

ASK Chemicals

Filters & Risers

Filters

Our filters are globally recognized as the highest quality in the industry. ASK Chemicals offers a full portfolio of metal filtration products for all metal types and applications, which includes UDICELL and EXACTFLO metal filtration products. We pride ourselves on being able to deliver quality products and solutions bundled with the highest level of experience and service to assist today's metal casters in successful implementations.

Types:

- UDICELL Filters

- UDICELL Investment Casting Filters

- EXACTFLO FIlters

- EXACTPORE™ 3D Filters

UDICELL FILTERS

Highly robust foundry filtration products recommended for high temperature alloys and/or heavy castings.

TYPES: UDICELL Zirconia Filters, UDICELL Carbon Bonded Filters, UDICELL Exactfill Housings

UDICELL

Zirconia Filters

UDICELL filters are fully sintered ceramic filters made of partially stabilized zirconia. These filters are specifically designed for use in steel and iron foundries. UDICELL filters have the highest chemical, thermal and mechanical stability in the industry, providing consistency and performance for high temperature alloys and/or large pouring weights. The UDICELL filter is a cost efficient means of reducing casting defects.

- Recommended pour sizes: 10 PPI - 15 PPI

- Recommended metal type: Stainless Steel / Low Alloy Steel

Advantages:

- Ability to withstand temperatures up to 3200°F

- High efficiency of molten metal filtration and turbulence reduction, providing laminar flow

- Captures non-metallic inclusions to improve casting properties (strength, ductility and fatigue resistance)

- Open pore structure provides repeatable pour times and flow rates

- Process control for the highest quality filters in the industry

UDICELL

Carbon Bonded Filters

UDICELL carbon bonded filters are used for ferrous alloys that may experience priming difficulties. The carbon bonded filters provide an excellent mix of priming efficiency with filtration effectiveness. A low percentage of carbon limits the possibility of contamination from carbon pick-up. UDICELL carbon bonded filters can be engineered in custom shapes, with a maximum dimension of 6” or 150 mm.

- Recommended pour sizes: 10 PPI - 15 PPI

- Recommended metal type: Stainless Steel / Low Alloy Steel

Advantages:

- Ideal for low pouring temperatures

- Efficient filtration and oxide reduction

- Multiple pour sizes

UDICELL

Exactfill Housings

Recommended pour size: 10 PPI

Recommended metal type:

Steel / LCLA / SS

Advantages:

- 3x greater filter area

- Self-supporting geometry

- Quick install & easy to use

Recommended pour size: 10 PPI

Recommended metal type:

Steel / Iron (Ductile) / Iron (Grey)

Advantages:

- 5 styles to support different uses

- Cost effective

- Quick install & easy to use

UDICELL

Investment Casting Filters

Consisting of UDICELL Zirconia & EXACTFLO Alumina – fulfill the highest demands for the production of ferrous and non-ferrous investment castings in the aerospace, energy and medical sectors as well as for commercial applications. Available for use in the shell mold itself, within a pouring cup, in-line with the runner system, or as gate filters all available in pore sizes ranging rom 10-45 PPI.

Available in a variety of special shapes, as well as dual pore sizes, tapered edges, edge coating and with high temperature fiber gaskets. ASK Chemicals also produces dam and cylindrical shaped filters for alloy manufacturers.

SEC = Smooth uniform edge coating for straight wall filters

FEC = Durable edge coating applied to tapers and special shapes

No Edge Coat = Standard filter webs

• It is preferred to cover the entire surface area of the filter as quickly as possible

• Greater metal head pressure helps filter flow and priming

Advantages:

- Capture of non-metallic inclusions to improve casting properties

- Reduction in molten metal turbulence and trapped gas

- Custom sizes and shapes differentiate us from other suppliers

EXACTFLO FILTERS

Highly robust foundry filtration products recommended for high temperature alloys and/or heavy castings.

TYPES: EXACTFLO Cellular Filters, EXACTFLO Silicon Carbide Filters, EXACTFLO Alumina/SiC Filters

EXACTFLO

Cellular Filters

EXACTFLO cellular filters are ideally suited for both grey and ductile iron, as well as non-ferrous alloys. EXACFLO cellular filters provide a highly repeatable cell structure to ensure repeatable performance in regards to molten metal flow control. EXACTFLO cellular filters have both chemical inertness and mechanical strength while providing a thermal robustness with alloys up to 1450˚C or 2650˚F.

- Recommended pour sizes: 100 csi (Ductile) and 200 - 300 csi (Grey)

- Recommended metal type: Iron (Ductile) / Iron (Grey)

Advantages:

- Engineered to ensure consistency

- Reduces trapped gas

- Square or round pores

EXACTFLO

Silicon Carbide Filters

Reticulated filters for increased metal cleanliness. EXACTFLO Silicone Carbide filters are ideally suited for both grey and ductile iron, as well as non-ferrous alloys. EXACTFLO SiC filters provide a highly porous, open structure with a tortuous path for metal flow resulting in cost effective and efficient removal of oxide inclusions. EXACTFLO SiC filters have chemical inertness and mechanical strength, while providing thermal robustness with alloys up to 1510˚C or 2750˚F.

- Recommended pour sizes: 10 - 15 PPI (Ductile) and 20 - 45 PPI (Grey)

- Recommended metal type: Iron (Ductile) / Iron (Grey)

Advantages:

- Removes inclusions

- Improves surface finish

- Provides laminar flow

EXACTFLO

Alumina/SiC Filters

- Recommended pour sizes: 10 PPI - 30 PPI

- Recommended metal type: Aluminum

Advantages:

- Removes inclusions

- Improves surface finish

- Provides laminar flow

EXACTPORE™

Customizable 3D Filters

for unmatched reliability and consistency

EXACTPORE™ 3D filters protect against filter bits by utilizing an engineered structural design capable of limitless shapes. In addition, this optimized structure offers nearly perfect pore sizes (e.g. 10 ppi). Before, this was not possible due to the variability inherent with reticulated foam filters. Now, any pore size – even untraditional sizes – can be used to ensure the most consistent flow characteristics. EXACTPORE™ 3D filters are produced using our world class operation with fully customizable options.

Advantages:

- Consistent flow rates & reduced filter bits

- 100% engineered designs & structure

- Increased flow rates / capacities

- Exact pore size requirements

- Customizable w/ first class manufacturing

EXACTCAST FLOATING COVER LIDS

EXACTCAST Floating Cover Lids replace the need to apply the typical powdered hot topping to open risers. They are much more consistent in performance than standard hot toppings due to the predetermined size and weight of the cover lid. The thickness of the lid is designed in proportion to the diameter of the riser. They are typically placed inside the feeder when the mold is closed and float up as the riser fills the molten metal. Floating cover lids are available in insulating / exothermic formulations.

*Not Available in Europe*

Advantages:

- Improved feeding consistency and performance

- Sized specifically for the riser - eliminates waste

- Reduced segregation

- Improved workplace safety

- Cover lids can be manually modified in a blind riser

- Cover lids help improve casting yield (due to shortness of blind riser)

EXACTCAST POURING CUP

EXACTCAST Pouring Cups are used to direct pouring applications, promoting directional solidification and increasing metal cleanliness. Containing high quality ASK Chemicals' filters. they are available for use in aluminum, grey iron, ductile iron, and steel applications. They are also available in sizes ranging from 2" to 7" diameter.

*Not Available in Europe*

Advantages:

- Improved productivity

- Improved casting yield

- Improved metal cleanliness

- Promotes directional solidification

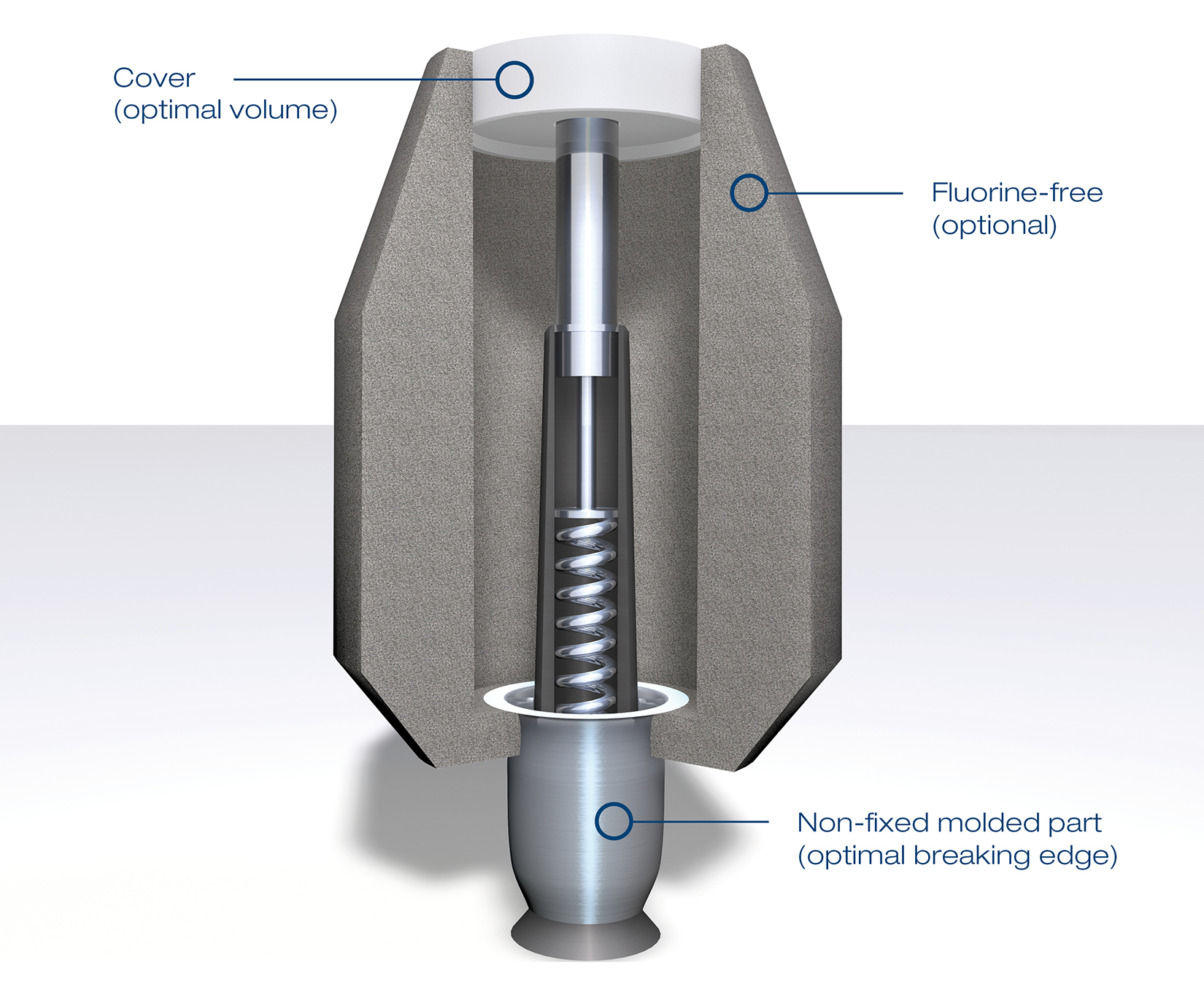

EXACTCAST MINI-RISERS

EXACTCAST Mini-Risers are thick-walled, highly efficient riser sleeves. Designed to be used to ram-up or spot-feeding applications, the fast igniting highly efficient exothermic / insulating sleeves allow for a 60-70% feed efficiency. This, in turn, promotes higher yields than typically found in traditional riser sleeves. These risers are ideal for feeding isolated sections or locations with limited contact areas.

ASK Chemicals EXACTCAST mini-risers also come in a wide variety of metal neck designs to further reduce contact area and, thus, finishing time / expense.

In addition to the traditional mini-riser design, a new RC series mini-riser design is available. This design offers reduced riser sleeve contacts, which facilitate easier removal of the risers from the castings.

Advantages:

- Highly efficient

- Maximized yields

- Reduced contact area

- Available in fluorine-free models

- Consistent thermal properties and performance

EXACTCAST KMV MINI-RISERS for optimum yield in steel applications

Conventional risers used in steel casting generally do not use the complete riser volume to counteract the shrinkage deficit. The output from these risers is just 30%. The remaining 70% of the volume is used to keep warm the 30% of the liquid metal required for feeding.

It is precisely here that the fiber-free EXACTCAST KMV mini-riser for steel casting comes into play. While retaining the feeding power, the volume can be reduced, as the exothermal mass replaces the non-feed.

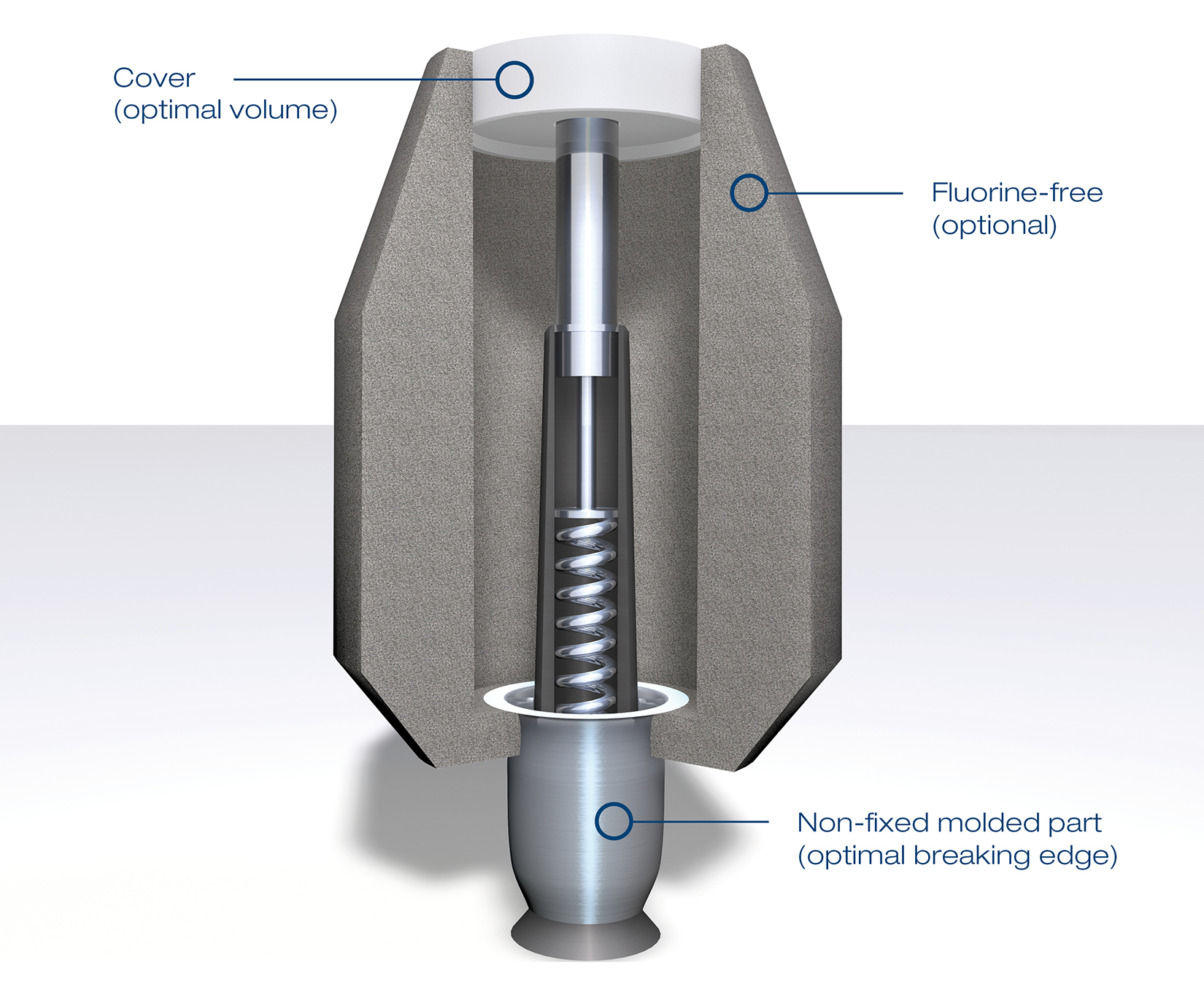

EXACTCAST OPTIMA RISERS for serial castings

The EXACTCAST OPTIMA risers have a loose integrated metal neck in the bottom part of the riser and the corresponding pin. These act as a precisely defined breaking point. The virtually frictionless sleeve and the integrated riser cap prevent crumbling particles from falling into the mold. Mold contamination and the associated casting defects are therefore eliminated, raising the cycle times on molding systems. Both variants are available fluorine-free.

EXACTCAST Fiber-Free Formulations

- IN Series: The IN Series is an insulating formula designed for use with all metals including steel up to a 4 inch / approx. 10 cm thickness.

- STL Series: The STL Series is a high grade insulating formula designed for use with heavier sectioned steel castings, 3.5 inches / approx. 9 cm thick and higher.

- EX Series: The EX Series is a standard grade exothermic formulation designed for use with all ferrous metals.

- EXF Series: The EXF series is a high performance, fast igniting, fluorine free, exothermic formulation which was developed to eliminate surface defects e.g. fish-eye defects associated with the green sand contamination by traditional fluoride containing exothermic riser sleeves. The low energy required to ignite these sleeves makes them very effective in cold riser applications. They can also be used in steel applications where a fast ignition is required.

EXACTCAST

Fluorine-Free Risers

for a clean environment and better casting

The fluorine-free risers from ASK Chemicals offer you crucial quality advantages and can eliminate fluorine contamination of the sand. This benefits both the environment and the foundry by reducing the quantity and disposal costs of the used sand.

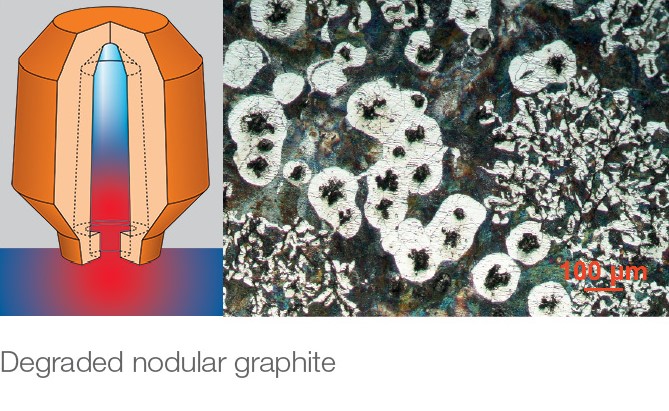

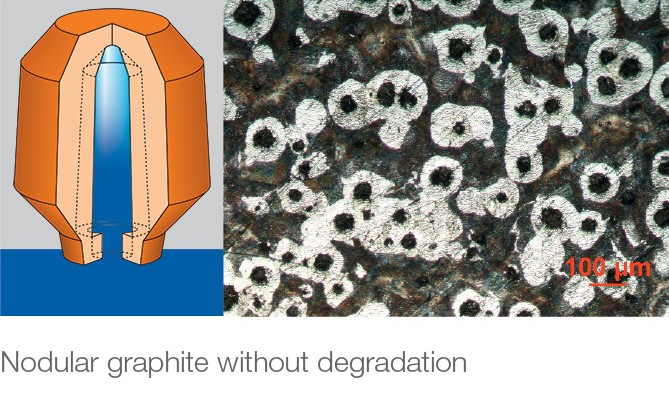

- Elimination of surface defects: The patented, fluorine-free risers from ASK Chemicals enhance productivity by eliminating surface defects caused by fluorine reactions.

- Reduction of graphite degeneration: The patented, fluorine-free recipe helps to minimize graphite degeneration in ductile iron that is usually encountered in the feeder's zone of action.

Want more information on specific products?

EXACTCAST Riser Sleeves

EXACTCAST CYLINDRICAL SLEEVES

EXACTCAST Cylindrical Sleeves are used primarily in open riser applications. They are available in both insulating and exothermic / insulating formulations.

Advantages:

- Dimensional accuracy

- Improved productivity

- Consistent thermal properties and performance

- Also made from low density, non-fibrous insulating materials

EXACTCAST INSERTABLE SLEEVES

ASK Chemicals insertable riser sleeves are produced using ASK Chemical's patented cold box process or with inorganic silicate binders. They are dimensionally accurate and high-performing. Available in several formulations (insulating, exothermic, and fluorine-free), our riser sleeves are sure to meet your metal casting needs. EXACTCAST insertable sleeves are also non-fibrous. Therefore, screen plugging during reclamation is of no concern. Moreover, their non-fibrous makeup eliminates potential defects such as deformation, springback, and inconsistent performance.

Advantages:

- Dimensional accuracy

- Increases productivity

- Low gas evolution

- Consistent thermal properties and performance

- Also made from low density, non-fibrous insulating materials

- Available in custom shapes and sizes for a multitude of applications

EXACTCAST NECKDOWN SLEEVES

ASK Chemicals EXACTCAST Neckdown Sleeves are used primarily in open riser applications. They are available in both insulating and exothermic / insulating formulations.

Advantages:

- Reduced contact area

- Dimensional accuracy

- Improved productivity

- Consistent thermal properties and performance

- Also made from low density, non-fibrous insulating materials