BINDER SYSTEMS

Binder Systems are materials used to bind sand grains together to create molds and cores for metal casting. They are crucial for ensuring the structural integrity, strength, and accuracy of molds through the casting process.

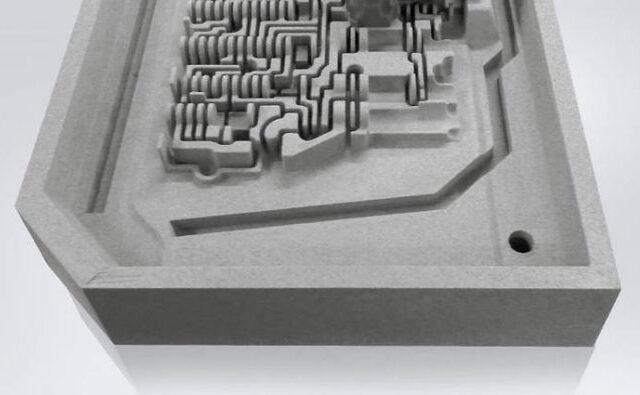

PU Cold Box Binder

High-performance advantages for the highest requirements

The Cold Box process is a high-performance, highly productive core manufacturing method that is used in large series production of cast parts in particular and features high process reliability and productivity. The defining feature of the cold box process is its high reactivity, which makes short production cycles possible for core production. ASK Chemicals has not only succeeded in further developing the process in terms of productivity but also with regard to humans and the environment.

Benefits:

- Benefits for both the environment and your staff

- Reduce odor in core production and casting

- Low emissions of BTX gases

- Low monomer content

- Low-odor, nonhazardous solvents

- Increases productivity

- Reduced cycle times enabled by rapid reactivity

- Increased tool availability resulting from reduced condensate contamination and decreased adhesion tendencies

- Cleaning the core box requires less work, saving time

- Long sand bench life due to high strength

- Increases quality

- Less casting defects due to process-optimized binders

- High dimensional consistency of the core during production and while coating is drying due to high strength

- High dimensional consistency during casting due to high deformation stability

- Exceptional core quality and stability achieved through superior process reliability and high strength levels

- Cost reduction benefits

- Reduced binder consumption due to higher efficiency

- Enhanced tool availability due to reduced condensate contamination and minimized adhesion tendencies

- Improved stability results in fewer rejected cores

- Reduced catalyst consumption due to high reactivity

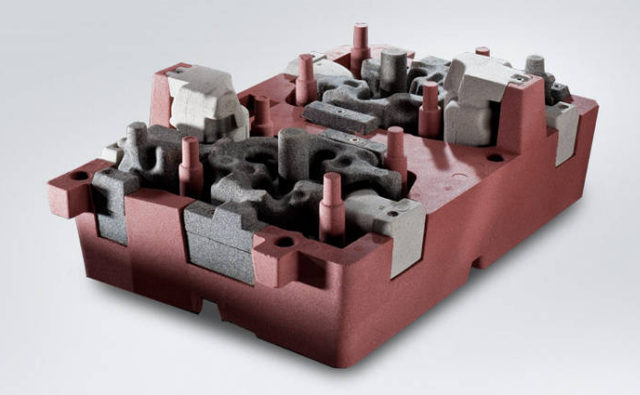

No-Bake Binder Systems

ASK Chemicals is a leader in developing

no-bake technology

ASK Chemicals has been a leader in developing No-Bake technology for many years. As innovators in the field, they have been developing and establishing the PEP SET system in foundries since the early 1970s. The development of PU No-Bake systems has revolutionized the manufacture of cores and molds in the foundry industry.

These solutions are invariably engineered to satisfy the key attributes desired by the market—improved quality, greater productivity, and environmental characteristics.

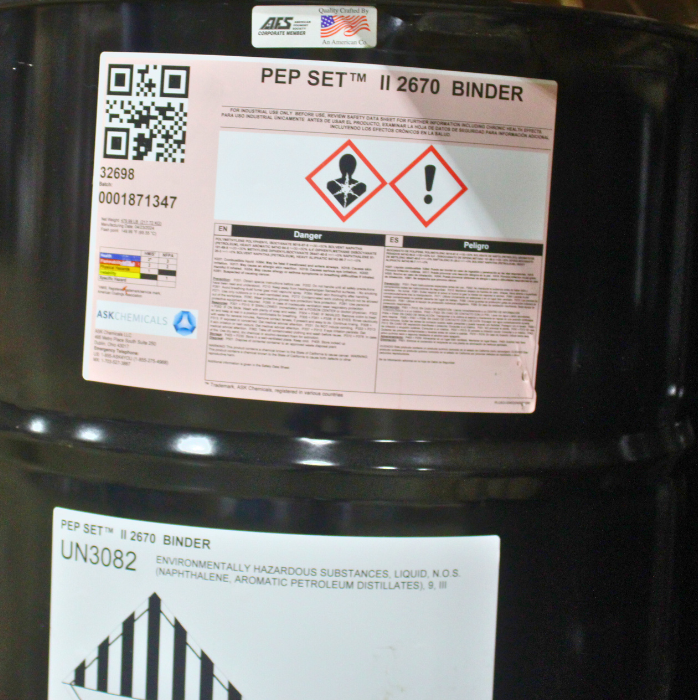

PEPSET™

Phenolic Urethane No-Bake

PEP SET is widely regarded as the most trusted name in the no-bake market and is known for its exceptional quality and highly controllable curing reactions. When placed on an automated roller-loop or turn table production line, it produces fully cured molds in less than 90 seconds, but the speed can be optimized with the superior quality of PEP SET Catalysts. PEP SET's application flexibility and ease of use make it the perfect solution for meeting any mold-making requirements.

Benefits:

- Predictable and repeatable cure times

- Superior work time / strip time ratio

- Excellent core and mold strengths

- Ease of reclamation (mechanically and thermally)

- Excellent shake-out and release

The PU No-Bake systems have revolutionized the manufacture of cores and molds in the foundry industry. PEP SET resins are available in several variations for performance, long work/strip times, smoke odor and other environmental benefits. Some of these varieties are PEP SET QUANTUM, PEP SET MAGNA, and PEP SET PATRIOT.

CHEM-REZ™

Furan No-Bake and Warm Box Resins

ASK Chemicals offers a wide range of furan no-bake and warm box resins. CHEM-REZ binders can be applied for all casting dimensions and metal types. A wide catalyst range can help tailor cure speeds to optimize your process. CHEM-REZ binders are available under the trade names: CHEM-REZ Fury, CHEM-REZ Flexset, and CHEM-REZ DURASET. Each of these sub-sets of the product line has resins with specific benefits for individual foundry needs.

Benefits:

- Excellent casting surface

- Controllable curing speed

- High strength

- Excellent shake-out and release

- Ease of reclamation (mechanically)

NOVASET™

Ester Cured No-Bake

This ester-curing water-based no-bake resin system is capable of being used in most casting processes. Its water-based nature reduces material handling requirements, as well as casting defects associated with solvent-based binder systems. This no-bake binder requires a liquid ester co-reactant to cure the resin. ASK Chemicals has a wide range of co-reactants allowing for all levels of productivity. NOVASET is ideal in most large-scale casting productions, especially in steel applications. Sand coated with NOVASET HK+ RESIN can be thermally reclaimed with the use of NOVATHERM™ RSA 40 as part of the reclamation process.

Benefits:

- Excellent casting surface

- Wide variety of co-reactants

- Eco-friendly organic binder system

- Ideal for use in steel casting production

Sand coated with NOVASET HK+ RESIN can be thermally reclaimed with the use of NOVATHERM™ RSA 40 as part of the reclamation process.

ACCOSET™

Sodium Silicate Binders

ACCOSET no-bake binders are water-based solutions of sodium silicate that can be hardened on sand by curing with an organic ester catalyst. They are all-purpose binders used to produce a variety of molds and exterior cores, which require high strengths for handling purposes.

Benefits:

- Several types are available depending on specific strength and shake-out needs

- Low smoke and odor

- A wide range of catalysts to determine work time/strip time

LINO-CURE™

Alkyd-Oil

LINO-CURE is an alkyd-oil three-part binder system that works well for large cores and molds. It has a long available work time and strip time with excellent stripping characteristics. It works well with high pH sands such as olivine.

Benefits:

- Works well with all metal types

- Excellent stripping characteristics for worn or complicated patterns

- Effective for large cores and molds

- Extended working and stripping times