OILS, RELEASE AGENTS, & HYDRAULIC FLUIDS

Oils, release agents, and hydraulic fluids are essential materials that support various processes and machinery involved in metal casting and production.

OILS

Oils are used for lubrication, cooling, and reducing wear in foundry equipment. They help maintain the smooth operation of machinery like molding lines, conveyors, and core-making machines, ensuring longevity and efficiency.

RELEASE AGENTS

Release agents are chemical compounds applied to molds, patterns, or cores to prevent molten metal or casting materials from adhering to surfaces. They ensure smooth part release, protect molds, improve the surface finish of the cast product, and are a crucial part in extending the life of the tooling and reducing any production delays caused by sticking issues.

HYDRAULIC FLUIDS

Hydraulic fluids are used in machinery systems like molding presses, die-casting machines, and robotic systems. These fluids transmit power while also providing lubrication and protecting components from wear, corrosion, and overheating. High-performance hydraulic fluids are essential for the safe and efficient operation of equipment under heavy-duty conditions.

All products play a vital role in optimizing production processes, ensuring safety, and maintaining high-quality standards.

Hydraulic Fluids

The GrifLube family of high-performing, biodegradable hydraulic fluids ensure protection in all types of hydraulic operations.

Griflube™

High-Performing Hydraulic Fluids

Whether you are looking for a fire-resistant, biodegradable, or need a hydraulic fluid to fit your most severe high-pressure application, Hill & Griffith has the solution. We also offer the Slide-Way lubricant series that is specially formulated using severely hydrotreated nathenic base oils and state-of-the-art additives.

Griflube™ Bio-Syn AS

Hydraulic Fluid

GRIFLUBE™ BIO-SYN AS

Griflube™ Bio-Syn is a biodegradable, fire-resistant, and factory-mutual approved high-performance hydraulic fluid. It provides exceptional lubrication and extended oxidation stability, as well as inherently fire resistant.

In response to an increased awareness and desire for environmentally compatible lubricants, Hill and Griffith developed the Griflube™ Bio-Syn as a high performance biodegradable hydraulic fluid, offering superior lubrication capacity. This advanced product technology not only conforms to the highest standards for low toxicity and biodegradability; but was specifically designed for the casting industry, where the reliability of hydraulic systems and the potential for combustion are typically an issue.

- Viscosity, SUS at 100°F: 214

- Specific Gravity: 0.92

- Flash Point (F): > 550°F

- Appearance: Translucent amber

Available in the following packaging sizes: Bulk Tank, Tote, Drums, and Pails.

- Full compatible with Houghton's Cosmolubric, Quaker's Quintolubric, Shell Irus and ACT's Ecosafe.

- Compatible with most commonly used seals and hoses, including Viton, Teflon, Silicone, Polyurethane, and Buna N.

Release Agents

High-performance foundry release agents for airset, cold box, dry parting, liquid parting, or shell applications.

Shell Release Agents

Release agents are used in various applications to release resin-bonded shell mold and cores in metal casting, where water sensitivity is not present. Hill & Griffith has formulated several silicone emulsions that produce outstanding release characteristics without creating build-up in the tool.

PACKAGING: DRUMS, PAILS

- Used in a variety of applications of mold or core release, where water sensitivity is not present.

- Easily used

- Non-flammable

- Excellent release

- Used in a wide variety of applications to release resin-bonded shell mold and/or cores in metal casting, where water sensitivity is not present.

- Oil phase withstands molding temperatures

- No smoking, breakdown, carbonization or buildup

- Non-flammable, dilutable with water up to 1:20

Cold Box Release Agents

The Cobra family of release agents provide excellent lubrication and release with minimal build-up on the pattern. They typically include chemical bonded cold box and no-bake systems, including water-sensitive materials such as sodium silicates.

PACKAGING: PAILS

- Wide variety of applications

- No Montreal Protocol regulations

- Excellent release

- Fast evaporation rate of the carrier

- Excellent lubrication and release with minimal build up on the pattern

- Cleans while it lubricates

- Economical

- Wide variety of applications

- No Montreal Protocol regulations

- Excellent release

- Excellent lubrication and release with minimal build up on the pattern

- Fast evaporation rate of the carrier

- Economical

- Wide variety of applications

- Zero volatile organic compounds

- No Montreal Protocol regulations

- Excellent release

- Excellent lubrication and release with minimal build up on the pattern

- Cost effective

Airset Release Agents

Formulated with unique release materials, pigments and solvents, the Airset family of release agents are fast drying and used when water is neither desirable nor tolerable.

PACKAGING: 25/LB PAILS

- Most economical aluminum pigment release

- Used when water is neither desirable nor tolerable

- Fast drying, easy application

- Minimum buildup

- Lessens downtime

- Used when release benefit of an aluminum pigment is required for difficult operations

- Long lasting

- Excellent release

- Good visibility on pattern

- Highest percentage of aluminum pigment in the release agent

- Used when water is neither desirable nor tolerable

- Fast drying, easy application

- Minimum buildup

- Lessens downtime

- Used when release benefit of an aluminum pigment is required for difficult operations

- Excellent release

- Good visibility on pattern

- Long lasting

- Fast drying, easy application

- Used when water is neither desirable nor tolerable

- Minimum buildup

- Lessens downtime

- Used when release benefit of an aluminum pigment is required for difficult operations

- Long lasting

- Good visibility on pattern

- Excellent release

Dry Partings Release Agents

Formulated with the highest quality mineral and chemical materials, these products are easily applied and used to aid in the releasing green sand molds and cores in all metal type applications. Dry Partings can also be used as an indicator between the cope and drag parting lines for assurance of a good fit.

PACKAGING: DRUMS, PAILS

- Good release

- Excellent visibility

- Easily applied

- Low waste

These products include:

- Avon Dry Parting-Premium White Parting

- Micro Part-Dry-Parting Containing Graphite

- Non Sil Parting-White Dry Parting (economical)

- No.12 Parting-Fine White Parting

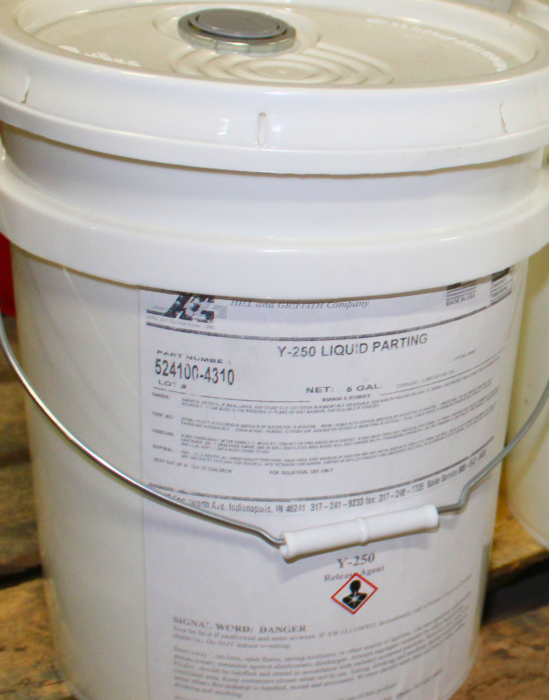

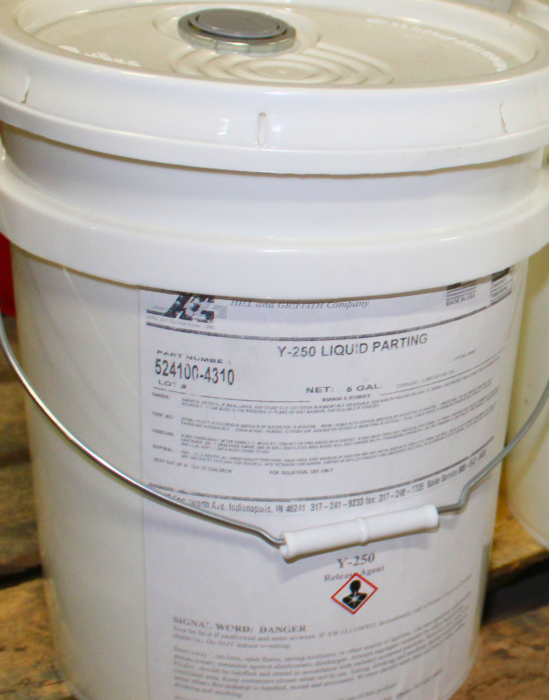

Liquid Parting Release Agents

Working with customers throughout the 125 years in the industry has allowed us to create trend-setting oils based pattern spray and the only water-based line in the industry that does not separate.

PACKAGING: TOTES, DRUMS, PAILS

- Eliminates flammability concerns in automatic molding operations

- Supports reduction of Seacoal in the molding sand

- Improves release of the molding sand from the pattern

- Improve casting surface of any iron type

- Low odor level benefiting operating personnel

- Requires fewer sprays per draw with clean releases and minimal buildup

- Eliminates flammability concerns in automatic molding operations

- Very low odor level benefiting operating personnel

- Minimizes airborne hydrocarbon emissions in the workplace

- Requires fewer sprays per draw with clean releases and minimal buildup

- Durable film provides rapid, clean releases

- Uniform atomization and spray pattern

- Hot sand does not affect performance

- Reduce cost through less application required

- Low VOC

- Flash point of 250°F minimum

- Inherently biodegradable

- For cleaner work room environment, airless applicators recommended

- Not Red labeled

- Flash point 270°F - 300°F

- No ash contents

- Non carcinogenic

- Applicable by conventional, airless or electrostatic sprayers

- Low VOC

- Inherently biodegradable

- Superior active ingredient reduces consumption

- Will not separate in cold-weather storage

- Shelf life is 2 years from manufactured date

- Durable film provides rapid, clean releases

- Contains pattern cleaner for brighter and shiny patterns

- Pleasant pine odor

- For cleaner work room environments, airless applicators are recommended

- Low VOC

- Inherently biodegradable

- Reduce cost through less application required

- Uniform atomization and spray pattern

- High flash point of 250°F minimum

- Not Red Labeled

- Hot sand does not negatively affect performance